Cylinder Head seals combustion chamber, houses valves & spark plugs, forms coolant passages, wit...

- Home

- About

- Product

- Aluminum Die Casting Molds

- Aluminum Die Castings

- Other Die Castings

- News

- FAQ

- Contact

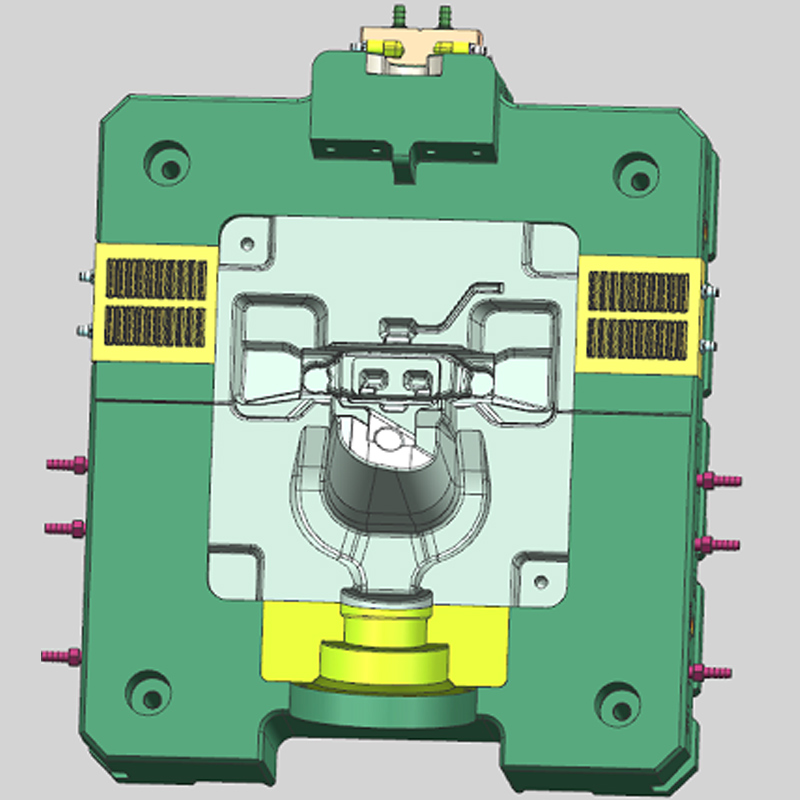

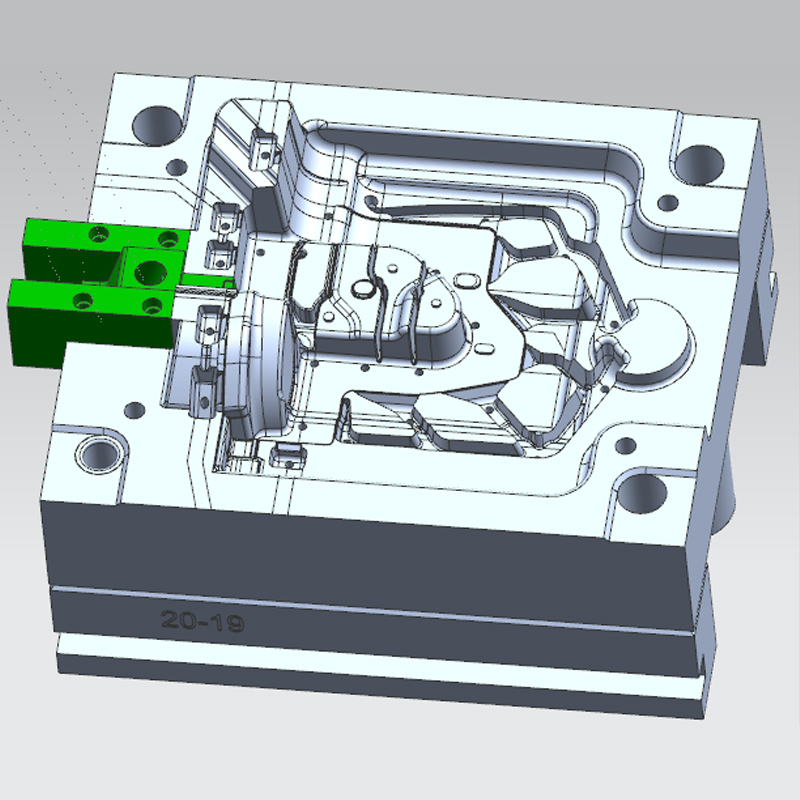

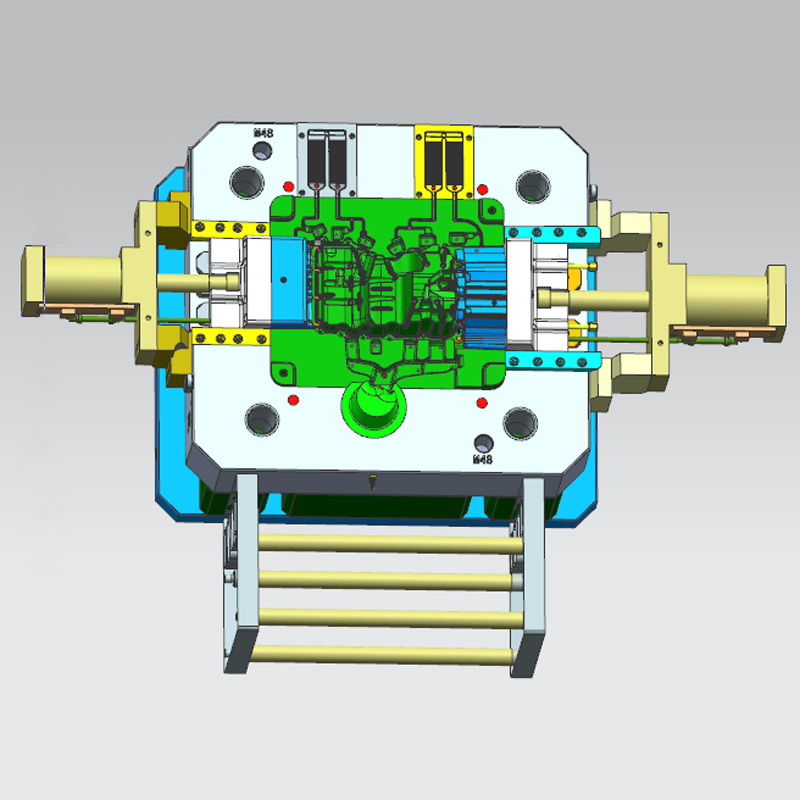

The camshaft bracket cover secures the camshaft position, seals oil channels to prevent leaks, blocks contaminants, and ensures stable lubrication system operation. the development of molds is a very high requirement.

Yunmai develops molds of high quality, and affordable price to meet the requirements of customers very well.

End-to-End Cost Efficiency

Integrated management from raw material to post-processing, 15%-20% lower total cost than competitors.

For high-strength load-bearing components, the high-pressure solidification castings produced by extrusion casting have a dense structure, no defects such as pores or looseness, refined grain size, and can be subjected to T6 heat treatment. Their mechanical properties are significantly higher than ordinary castings and close to the level of forgings of the same alloy, making them an excellent process for achieving lightweight.

In order to keep up with the trend of new energy vehicle development, combined with rapid iteration, and meet the road testing needs of small batch parts for OEMs, fast sample molds are produced in a more economical way, with fast delivery times and consistent performance with die-casting products. (The fastest delivery time is 14 days, with a lifespan of 1000 times)

Keeping up with market demand and customers' increasingly high requirements for parts, the mold development cycle is becoming shorter, and the stability and qualification rate of the mold are improving. Through the reasonable design of the sprue and special heat treatment of the material, we have produced molds made of domestically produced H13 material with a lifespan of 120000 molds.

Collaborative development and design optimization.

CAE Model Flow Analysis Software. Mold designers: 4 people. The average working experience is 10 years.

More than 20 CNC machining equipment: CNC, High-speed machines, EDM electrical discharge machines, wire cutting machines, milling machines, and other equipment.

The company has measuring equipment such as Sirui CMM hardness tester to ensure the accuracy of molds.

Yunmai Precision, its predecessor JYD Mould factory was founded in 2012. We are a professional factory specializing in the design and manufacturing of aluminum die-casting molds and aluminum die-casting items, known for our high-end mold design and competitive pricing. Since its establishment, we have provided high-quality mold solutions to many well-known companies, including automotive giants such as Tesla, BYD, and Volkswagen, as well as leading communication industry players like Huawei, etc.

As a famous China Aluminum Camshaft bracket cover mold Suppliers and Aluminum Camshaft bracket cover mold Factory, we offer one-stop services, including mold design, manufacturing, trial molding, small-batch prototyping, mass production, and quality control. We are committed to delivering exceptional aluminum die-casting mold solutions through innovative technology and superior service. Our molds are renowned for their high precision, durability, and production efficiency, meeting diverse customer needs.

Yunmai Precision from China and located in Ningbo Beilun, which is about 210km distance to Shanghai and 10km to Ningbo port. Ensures efficient logistics and quick response to global customer demands.

Make the most cost-performance aluminum die-casting mold

Bring the best product experience to customers

High-Quality Materials: We use premium world-wild well-known materials to ensure durability and superior performance.

Advanced Technology: Utilizing the latest die-casting mold design technology and equipment to guarantee product precision and consistency.

Customization Services: Offering personalized design and production based on customer needs to meet various application scenarios.

Cost-Effectiveness: Providing high-cost-performance products through optimized production processes and scale production.

Fast Delivery: Efficient supply chain management and production planning ensure timely delivery.

Global Certifications: Products comply with international standards and hold multiple quality certifications, ensuring global applicability.

Excellent After-Sales Service: Providing comprehensive technical support and after-sales service to address customer concerns.

In today's era of rapid digital development, communication equipment is the core hub of information transmission, and it...

View MoreAs a core component in engine manufacturing, the aluminum alloy cylinder head mold is designed to operate stably for a l...

View MoreAutomotive Industry: In the automotive sector, Magnesium Alloy Die Castings are used extensively to reduce vehicle weigh...

View MoreGating System Design: The gating system in the mold controls how molten aluminum enters the cavity. By optimizing the de...

View MoreThe lightweight and good formability of automobile components aluminum die castings make them an important choice to rep...

View More